How to Select a Power Moller

PM486FE-60-366-D-024-KF

PM: Power Moller

Model: 486FE

Speed Code: 60

Tube Length: 366

Voltage: D-024 (DC 24V)

Mounting Brackets: KF (no mounting brackets)

1. Material

What is in contact with the Motorized Roller?

- Metal

- Plastic

- Wood

- Urethane

- Natural rubber

- Corrugated cardboard

- Other material

2. Product Weight

What will be the maximum weight?

3. Available Voltage

What voltage are you using?

- 24V DC

4. Desired Transportation Speed

How fast do you want to move the article?

- Feet/minute (FPM)

5. Roller Diameter

What diameter are you looking for?

Common Itoh Roller Diameters

- 1.50” (38.0mm)

- 1.91” (48.6mm)

- 2.25” (57.0mm)

- 2.38” (60.5mm)

- 2.50” (63.5mm)

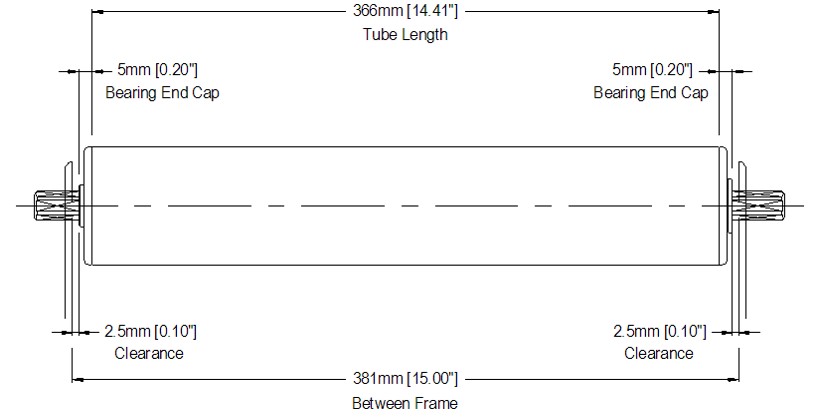

6. Between-Frame (BF) Dimension

What is your between-frame dimension (BF)?

- In determining the correct length of the Power Moller required, you should first obtain the between-frame width of the conveyor you will be mounting the Power Moller in.

- All dimensions need to be converted to millimeters.

- BF in inches x 25.4 mm = BF in millimeters

- Always round your BF in millimeters to the nearest whole number (e.g. a BF of 366.4 mm should be rounded to 366 mm, and a BF of 366.5 mm should be rounded to 367 mm)

- Take the between-frame width in millimeters and subtract 15mm to account for bearing end caps and clearances to achieve proper tube length.

- Subtract 21 mm when using the “JQ” type shafts.

- For the PM635, the deduction will be 20mm

Please reference the product catalog pages for proper deduct measurements for specific roller options.

7. Options

Does the application call for any special options?

- Lagging (Natural Rubber, NBR, Neoprene, Urethane)

- Dust-proof (DP)

- Waterproof (WA)

- Brake (BR)

- Grooves (P2- standard locations vary by roller model)

- OS – Non-standard groove location, sprockets welded to tube, welded key stock

- KF – Brackets not ordered with roller (if brackets are priced in with roller, KF is not needed)

Please reference the product catalog pages for options for each roller model. Options vary by model.

Important Formulas

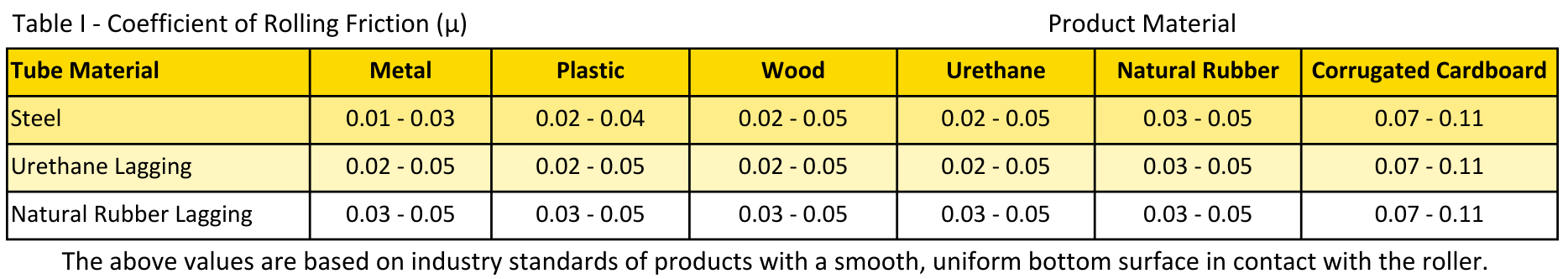

Tangential Force (TF)

- Tangential force is the force in lbs. that is needed to move the item on the conveyor.

- The force tangent to the roller’s surface.

- Tangential force F can be found by the following formula:

Formula 1

TF = µ X W

TF = Required tangential force

W= Weight of article to be transferred

µ = Coefficient of rolling friction in accordance with the material composition

of the bottom of the article to be transferred. (See Table I)

- To determine the number of POWER MOLLER units required for transfer, compare required tangential force (F) and the tangential force of one POWER MOLLER unit (f)

Formula 2

Number of POWER MOLLERS required = F/f